Spark Testing

Knowing exactly what your pipe is made of is critical.

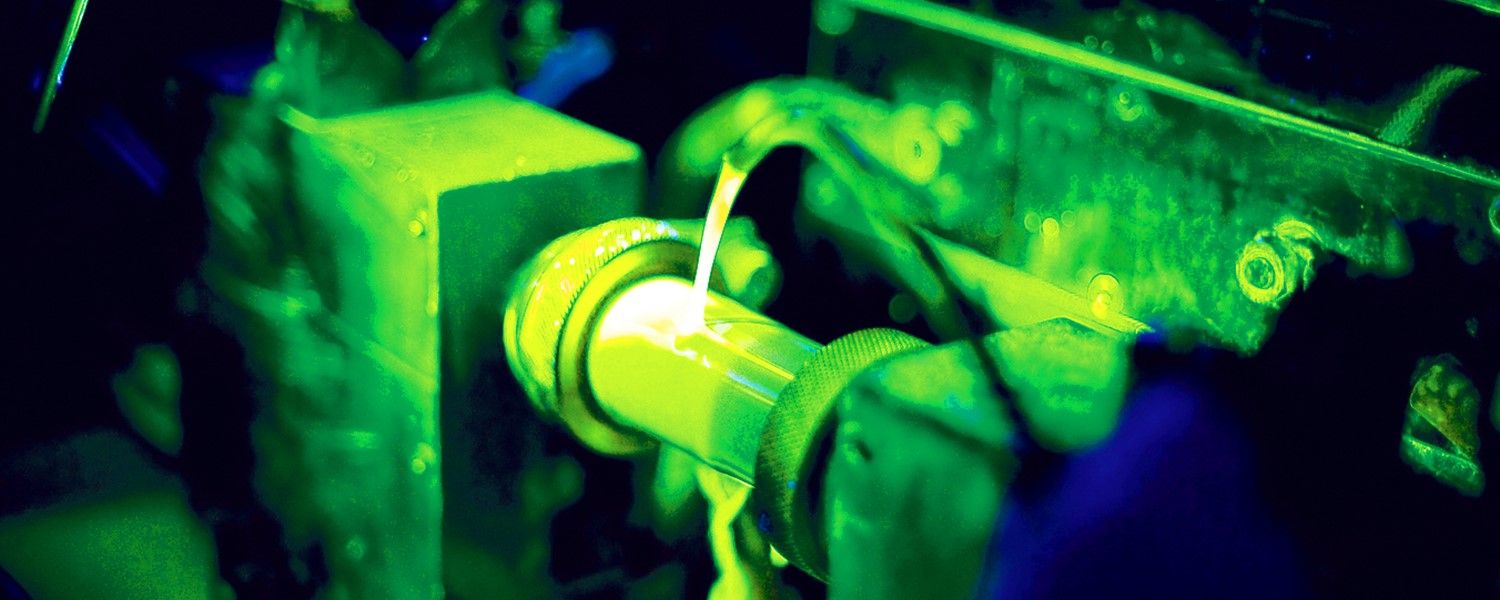

Spark Testing, or Optical Emission Spectroscopy, is the process Pro Integrity NDT® uses to identify the elemental properties of metal.

We conduct tests in an envelope of argon while our instruments measure the visible spectrum of light emitted by minute quantities of the metal that are “burned” by an electric spark.

Spark Testing produces quick, reliable and reproducible analysis. It can analyze a wide variety of elements, including steel, cast iron and high alloyed steels, non-ferrous metals and their alloys, wrought alloys, casting alloys, bronze, brass, copper, nickel, magnesium, zinc and many others.It offers a good limit of detection for most materials - generally less than 50ppm, with 10ppm detection limits more typical.

Benefits of this method are:

- The carbon content of stainless or low alloy steels can be measured

- It can differentiate between 304/316 and 304L/316L Stainless

- The Ferrite equivalent of steel can be calculated if magnetic method fails

- Provides input data to Carbon Equivalency calculation

HandySCAN 3D Laser Scanning

A fast and accurate inspection solution for surface damage assessment

Creaform’s VXIntegrity

The NEW VXintegrity platform is a dedicated 3D assessment software tool designed for the inspection of damage on various surface geometries. Three of the four modules, combined with a Creaform 3D scanner, will give NDT service providers the tools to offer their clients in-depth and accurate inspections on their assets.

Accurate Inspection Results

The combination of Creaform’s industry leading metrology-grade 3D scanners and the VXintegrity analysis modules ensures repeatable and traceable measurement results. More accurate and faster than traditional methods like the pit gauge, the solution limits the operators' impact on the analysis and shortens the time needed to generate in-depth final reports.

Key Features

For pipeline NDT, the Pipeline module (also known as Pipecheck) delivers accurate pit-gauge results and in- depth burst pressure calculations. For refineries and plants, the Surface Damage module offers a way to measure metal thickness loss on complex geometries. For preventative maintenance, the Damage Monitoring module allows for confident assessment of variations in asset geometry, even over time.

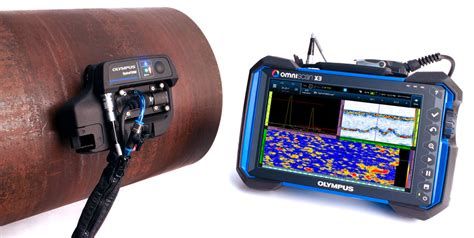

HydroFORM2 Scanner

Advanced Ultrasonic Testing

Easy to deploy and optimized for one-person operation, the HydroFORM™ scanner is a complete 2D encoding corrosion mapping solution. Equipped with our ScanDeck™ module offering acquisition instrument feedback and control functions and an integrated index axis encoder, it enables fast and reliable phased array (PA) two-axis scanning.

Acquire high-resolution data of pipes and large surfaces in minimal time for efficient and reliable wall-thickness mapping and midwall damage detection. The unique water-column system enables inspection of curvatures 4 in. OD (101 mm) and up.

Phased Array

Permanent Records

Automated Ultrasonics (AUT), sometimes called Advanced Ultrasonics, employs the same high frequency sound wave principles applied in conventional Ultrasonics. Using AUT, Pro Integrity NDT® can also provide a permanent record of the inspection. We use computer-controlled mechanized scanners to acquire the inspection data, which can then be re-evaluated as required or compared with data gathered at future inspections.

Automated Ultrasonics can often be preferable to Radiography because it is safer, quicker and usually more cost effective. Pro Integrity NDT uses AUT to conduct complete volumetric inspections of welds and adjacent material. Inspections of longitudinal and circumferential welds on piping and vessels are common applications, while more specialized applications for components such as nozzle welds, along with and corrosion and thickness mapping in materials, are also possible.

We specialize in the use of Phased Array (PA) Automated Ultrasonics, an advanced welding inspection technology capable of recording multiple angle beams simultaneously.

A PA probe utilizes several independently pulsed ultrasonic transducers. The timing of those pulses can be varied to guide the beam electronically. Typical scanning patterns include sectorial scanning, in which the beam is swept along the test area similar to a searchlight, and linear scanning, which moves the beam from the back to the front of the probe while maintaining a consistent angle. The combination of data from multiple beams creates an image depicting a virtual slice through the test object.

Benefits of this method are:

- Fast, reliable and highly reproducible inspections

- Is safe for other employees to work around

- Provides a permanent record of inspection

- Computer controlled data acquisition

- Delivers complete volumetric coverage of welds

- Accurate height and length sizing of defects

In-service Welding Inspection

Asset Integrity Services - Assuring Compliance

Welding on in-service pipelines has grown exponentially. The result has been an increase in government regulation and monitoring.

The critical nature of this task requires experienced NDT / Asset Integrity Specialists to ensure that the pipe is safe and free of defects, welders are adhering to your procedures, and that the necessary controls to do this job safely are in place. It is important that people doing this type of work thoroughly understand pipeline integrity, new construction, and welding processes.

Pro Integrity NDT® has the knowledge and experience to meet those requirements

We supply industry-leading full service NDT, QC, and Project Management for fitting installations. Our service includes a full verification and documentation system, a thorough NDT pre-weld, in-process, and weld completion inspection, and a post weld 48-hour inspection as standard practice. This provides you and your clients with assurance that the welding process meets your high standards.

We also have extensive experience in completing Quality Control packages, reviewing and ensuring that the Inspection Test Procedures (ITP) are followed properly and signed-off. Pro Integrity NDT® also delivers turnkey reporting to document your installations step by step, giving you all-important trace ability and audit ready reporting with every fitting installation!

Our company will work with you to customize and implement a standardized reporting structure with all the essential information required, ensuring your quality assurance goals are met every time.

Pipeline Integrity Services

Responsible Data Collection and Audit Ready Reporting

Pre-Assessment

The Client's Asset information inclusive of the Historical and current data is collected and analyzed to prioritize pipeline segments. Pipeline segments are analyzed with respect to Anomalies, SCC, and Mechanical Damage susceptibility. The data is utilized in selecting specific sites along the pipeline R.O.W for Direct Examinations.

Indirect Inspection

Additional data is collected as deemed necessary by the owner / operator to prioritize the selection of segments and dig site selection. Typical indirect inspection methods utilized are close interval surveys (CIS), direct current voltage gradient (DCVG), alternating current voltage gradient (ACVG), and Pipeline Current Mapper (PCM). ILI Tool data once analyzed is also considered and may be all that is required before a dig program is commenced. Additional information about terrain conditions such as soils, topography, drainage etc. is also collected. The Integrity Management Plan (IMP) is then initiated.

Direct Inspection

Procedures to field-verify selected sites detailed in the initial analysis are performed and dig programs are initiated. Above ground measurements and field inspections are documented. The Pro Integrity NDT® team is well trained to perform the initial site data collection directly. Consistent and integrity based data collection such as: soils, drainage, topography, coating condition, anomaly identification and assessment, are all utilized to assess your pipeline conditions. ILI Tool information and the NDT technician's direct observations can confirm and quantify the presence and or severity of coating anomalies, corrosion, geometric defects and SCC/Linear indications.

Post Assessment and Mitigation

The hard data collected from the above steps are taken into account by project engineers to help determine whether a repair or mitigation is required.

Ultrasonics

A Sound Level of Service

Ultrasonics is a time-tested industry-standard method of asset testing. Pro Integrity NDT® is very experienced in the operation of Ultrasonic equipment used to detect internal and external defects in welding, materials, and components.

Ultrasonic inspection provides a visual indication of internal any material defects such as corrosion, even when those defects are not visible at the surface.

Ultrasonics is a proven method of detecting anomalies in welding, plate, pipe, forgings, and other components. Using Ultrasonics, Pro Integrity NDT can provide complete volumetric coverage for welds or material inspection. We can also use it to detect lack of bonding in clad and overlaid components.

Benefits of this method are:

- Extremely portable

- Best method for detecting internal and planar discontinuities

- Can be used on a wide variety of materials

- Instant results

- Only one side of the part is needed for testing

- Adaptable to automated systems

- Depth of penetration for flaw detection or measurement is superior to other methods

- Very safe form of testing for the technician and materials

Magnetic Particle Inspection

Simple, Fast Detection of Surface Discontinuities

With time being a crucial factor, Pro Integrity NDT® is able to use Magnetic Particle Inspection (MT) to detect surface and near surface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and certain alloys. MT can accurately assess the position, dimensions, form and range of deficiencies, but because MT cannot penetrate very far beneath the surface being examined, we use it primarily to detect surface discontinuities.

The principles are relatively straightforward. A magnetic field is induced into the metal being examined, and magnetic particles are applied to the surface, either as a powder or mixed with a liquid medium. A variety of particle colours are available to best highlight flaws in the tested material. Particles collect and gather around the magnetic flux leakage that surrounds any defects. We typically use MT for welds, castings, forgings, valves, machined parts, pressure vessels, and structural steel.

Benefits of this method are:

- Economical

- Simple and fast

- Extremely portable

- Can even work through thin layers of paint

- Large surface areas of complex parts can be inspected rapidly

- Best at detecting fine, shallow surface cracks

Asset Integrity Testing

Data Collection

We provide experienced senior NDT technicians that are able to fulfil your needs and all regulatory requirements. Our accomplished team thoroughly understands those regulatory requirements along with the importance of reproducibility so that results can be used comparatively year to year. Our standardized method of collecting and reporting the data ensures that you always have quick and easy access to the required information.

The ability to efficiently retrieve photos and drawings combined with the capacity to correlate data over the long term adds value and peace of mind to any Asset Integrity Management Program.

Hardness Testing

Determining the Strength of Your Materials

In many applications it is useful to know how well a material will resist scratching, deformation, or cutting. Pro Integrity NDT® uses Hardness Testing (HT) to make that determination.

We use several methods to measure hardness, including Brinell, Rockwell, and Vickers. The method used depends on the material and the hardness range. The results of these tests can be used to predict the tensile strength of a material, to determine its suitability for a particular application, and to monitor the effects of heat treatment.

We have 2 techniques available to us:

- Telebrineller. A tiny dent is made simultaneously in the material being examined and on the surface of a bar of known hardness, using a hammer and ball bearing apparatus. The diameters of the dents are measured, and the difference in their sizes determines the hardness value of the tested material.

- Ultrasonic Contact Impedance (UCI) A diamond indenter vibrating at ultrasonic frequency is pressed into the material being examined. As it penetrates the material, the frequency of the vibration shifts proportionally. The instrument is calibrated to the frequency shift found during the test of a known hardness standard, and thus the hardness of the tested material can be inferred.

Benefits of this method are:

- Telebrineller deforms a much larger surface area of material, so any errors due to steel crystal structure are minimized.

- CI leaves a very small testing defect on the surface of machined parts.

Liquid Penetrant Inspection

Detecting Surface Discontinuities

When a quick, economic analysis is desired, Pro Integrity NDT® uses Liquid Penetrant Inspection (PT) to detect surface discontinuities. In PT a dye is applied to the surface of a component. Through capillary action, the dye penetrates into surface discontinuities. After a set amount of time, the dye is removed from the surface and a developer is applied. The developer draws penetrated dye to the surface, and the discontinuity is clearly indicated.

Benefits of this method are:

- Can be used on a wide variety of materials and parts

- Extremely portable

- Simple and fast

- Can easily detect discontinuities as small as 4 µin or 0.1 µm

- Economical

- Detects all surface discontinuities in one operation

- Indications are produced directly on surface of the part providing a visual image of the discontinuity

- Can be used on ferrous & non-ferrous materials

QA / QC Technical Services

Pro Integrity NDT offers a multitude of QA / QC technical services

We provide you with turnkey solutions for your specific needs

As an outsourcing partner, we manage all aspects of manpower logistics, safety, procedures and any additional requirements you need to complete your projects. Pro Integrity provides the highest value added service teams to exceed client expectations. Our presence on the ground and proven track record places Pro Integrity in a strategic position to respond immediately and effectively to our client’s business needs.

Various Facilities - Engineering - Construction - Commercial

Services we provide include but not limited to:

- Project Management Personnel

- Project Controls Personnel

- Professional Engineers

- Superintendents

- Coordinators

- QA/QC Personnel CWB CERTIFIED

- API / NACE Personnel

- NDE- CGSB /SNT Technicians

- Level III CGSB / ASNT Auditors

- Document Control / Administration

- Alberta In-Service and National Board

Level III Services

Auditing, Documentation, and Training Services

Keeping up with regulatory requirements can become overwhelming at times. That’s why Pro Integrity NDT® also provides Corporate Level III services. We can assist in auditing, documentation, training, consultation, and drafting of procedures.

We can document customer-specific inspection procedures, develop in-house training documents or create qualification and certification of personnel programs. We can also develop customer-specific training and examinations for MPI and LPI level II certification.